‘Repair not replace’ approach set to deliver results for Scottish businesses

When Jamie Burns established Ailsa Reliability Solutions in 2020, his 20 years of experience in supporting customers, with various services, across a multitude of industry sectors, helped him create a business that was going to positively impact a lot of people.

Supporting the circular economy

The goal was clear – deliver towards a circular economy and get rid of the ‘just replace it attitude’ by keeping equipment running for longer while saving clients money by eliminating unplanned downtime and reducing wasted energy within their processes.

Jamie commented: “You could say it was my ‘Goal in Life’ – As somebody who is really aware of the fact we need to make changes now to improve the environment for the future, I wanted to create an independent organisation specialising in solutions to improve the reliability and availability of our customers’ plant and assets, using the latest condition monitoring equipment and technology available.

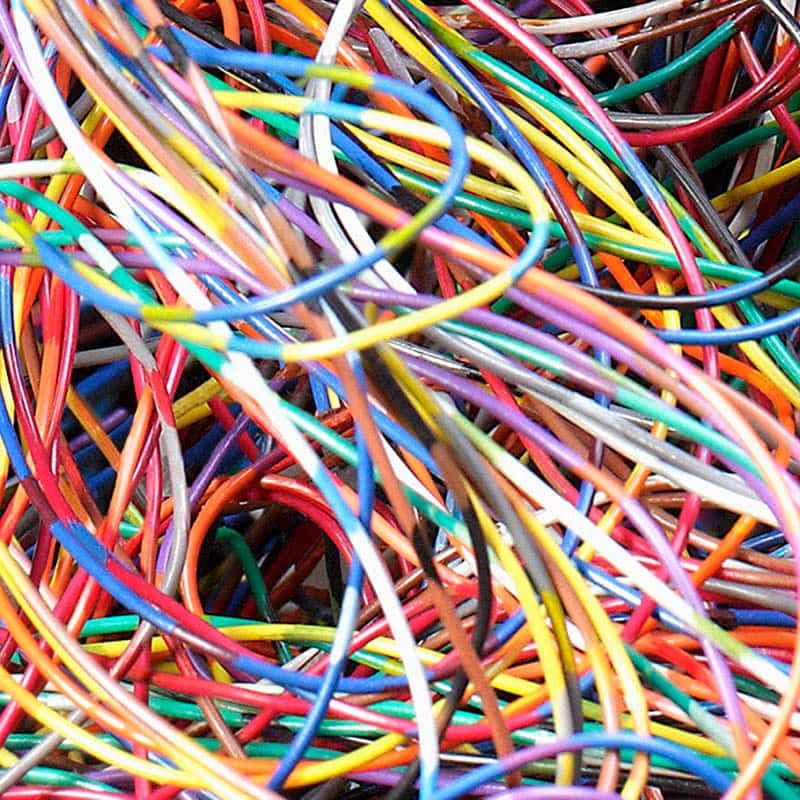

“New electric motors and fans were becoming a ‘consumable’ and cheaper option. By the time many businesses were considering repairing, there was so much damage to the equipment it was often just cheaper to replace.

“By catching the problem before it becomes an issue, and in many cases just doing a minor repair, there was no need for an expensive replacement.

“This approach would support a circular economy, especially as many of the replacements were coming from China or further afield, so the environmental impact could also be huge.”

Increasing customer productivity

The team can test, monitor, analyse, report and recommend solutions to critical items of mechanical and electrical plant to assure customers of maximum uptime and availability, and reduce costly downtime and unplanned outages, thus increasing customer productivity and profitability.

Jamie added: “We want to complete the circle – let’s stop running things to destruction and then simply replacing them. Let’s try and mitigate those risks and catch them before they become an issue. “Motors, generators, pumps, fans, gearboxes and any electrical/mechanical industrial equipment mainly around the rotational element can all be maintained and managed before they become damaged beyond repair.

“Businesses across the country are simply going to have to focus on this more than ever to meet UN sustainability goals, so for me, doing what we do will help change that mindset.”

Winning the Scottish EDGE competition, which is sponsored by Zero Waste Scotland gave Ailsa Reliability Solutions access to a wider network, and they joined the Net Zero Accelerator Programme to focus the operation for the future.

Over a period of 12 months, Ailsa Reliability Solutions has saved clients over £1.5 million in unplanned downtime and contributed to significant gigawatts of green electricity generation.

“We want to grow Ailsa Reliability Solutions to be a company of scale which helps businesses across the globe. We aim to save clients in the region of about £10 million by removing the replacement mindset, which we hope will support a circular economy,”