Funding sees strong wind success for Scotland’s leading refurbishment specialists

Wind is the future of power generation, in fact, Britain’s wind farms generated more electricity in the first quarter of 2023 than gas for the first time.

Improving green technology

Renewable Parts is Scotland’s leading supply chain and refurbishment specialist in the wind energy sector, and the only company in the UK working with original equipment manufacturers and major utilities to create a circular wind industry.

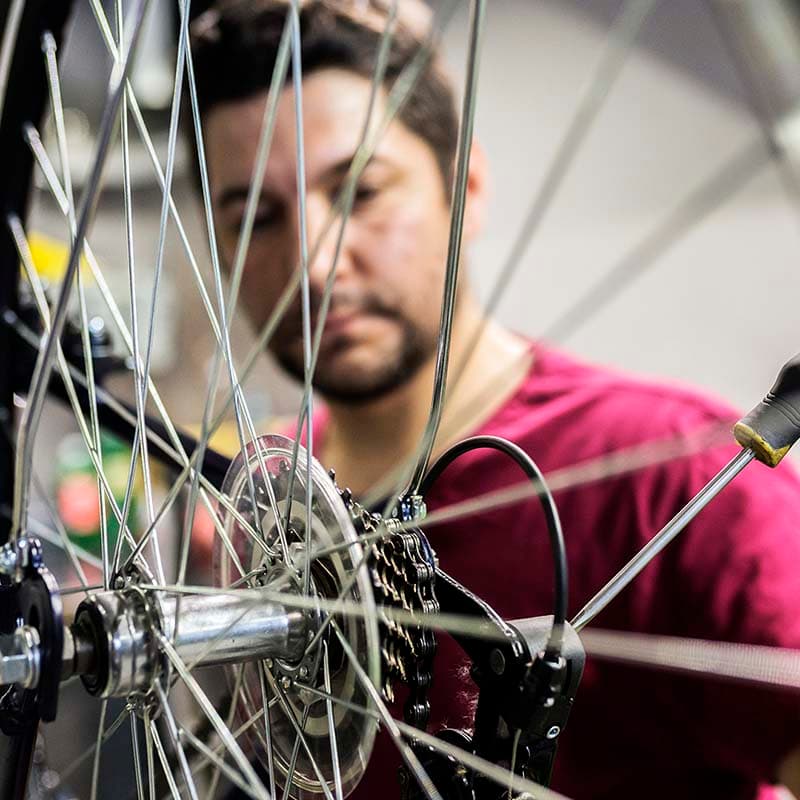

Focusing on the continuous improvement of green technology, Renewable Parts has the circular economy at its core. Defective and used wind turbine parts are taken to its Innovation Centre in the rural setting of Lochgilphead, Argyll and Bute, where the team of trained specialists apply the latest techniques to restore unserviceable parts to new condition. These parts are then recirculated into the industry.

This circular structure allows Renewable Parts to help suppliers reduce their carbon footprint and contribute to the overall low-cost, low-carbon energy that citizens benefit from. Refurbishing turbines has diverted around 198 tonnes of material from landfill since 2018, the equivalent of 130 Olympic-sized swimming pools.

Funding

Through its Circular Economy Investment Fund (CEIF), Zero Waste Scotland provided Renewable Parts with a cash injection of £171,445 to acquire a dedicated refurbishment remanufacture workshop and equipment. Double the size of its original refurbishment centre, the new building allowed the team to take on an additional 15 employees and double the number of its suppliers.

This funding has helped Renewable Parts refurbishment business increase by over 500% in the last three years to meet the growing demand for sustainable products from the wind sector, alongside an upsurge in its turnover by 37% year on year. Renewable Parts has saved 579 tonnes of CO2 equivalent since 2018 – the same as a double-decker bus circumnavigating the globe 11.5 times.

The pioneering business continues to raise awareness of circularity benefits to a traditionally risk-averse industry. With the UK and Scottish governments focused on reducing carbon emissions and developing the green industry, Renewable Parts actively speaks to its customers about the circular economy, how they can reduce carbon and waste by purchasing new replacement parts that are cheaper, more readily available, and ultimately cuts out carbon that is expelled when making brand new products.

Inspiring the next generation

Always looking towards the future and anticipating customer demand, Renewable Parts has a large focus on the offshore market as these turbine models come to a point where they enter self-perform maintenance and parts usage increases.

The goal is to get as many offshore organisations as possible to consider refurbished parts instead of new parts, ultimately saving manufacturer resource and unnecessary road miles. Passionate about getting the next generation engaged in the circular economy, the team regularly speaks at STEM events at schools and colleges, and employs on attitude over experience and skills, with a commitment to get them trained up once they are part of the business.

A recent collaboration with the University of Strathclyde and SSE Renewables has propelled the development of a circular economy within the wind sector, showing Renewable Parts’ efforts to get the next generation talking. Zero Waste Scotland’s support couldn’t have come at a better time for Renewable Parts, and General Manager, Michael Forbes, explains why.

He said: “There’s been a huge demand for refurbishment services and the remanufacture of parts that would previously have been scrapped. By applying our advance techniques we can bring these parts back to life.

“Zero Waste Scotland’s CEIF funding allowed us to move at a rapid speed, scaling the business with the purchase of a larger premises and specialist equipment to increase our output rate. We’ve taken on 15 employees to meet the demand, quadrupling our staffing needs.

We have a particular focus on hiring both modern and graduate apprentices, trained in-house, giving locals in Lochgilphead an opportunity to enter the green energy industry.

“Our business model, which has been enhanced with Zero Waste Scotland’s support and Highlands and Islands Enterprise’s guidance, is award-winning, and we’re proud to have taken home a variety of prestigious accolades over the past few years. Last year we scooped the 2022 Ashden Award for Energy Innovation, and in 2021 took The Spectator Economic Innovator of the Year Award for Scotland and Northern Ireland, and a 2020 Scottish Green Energy Award.”

“You have to have a rock-solid belief and plenty of resilience. Vision is vital for improving your business structure and becoming circular, you’ve got to find momentum and establish key stakeholders, both internally and externally, who can support your vision.”